This is some of my homemade tools, Boblon ask in another thread what I used to hollow out my hollow forms and i thought I would post a few of my homemade tools for you all to see.

Here is the captured hollowing rig it also has a laser mounted on the arm thats above the cutting end of the rig but it was not on at the time of the pic its made from 1" pipe 3/4" pipe and 2 1/2" flat bar stock

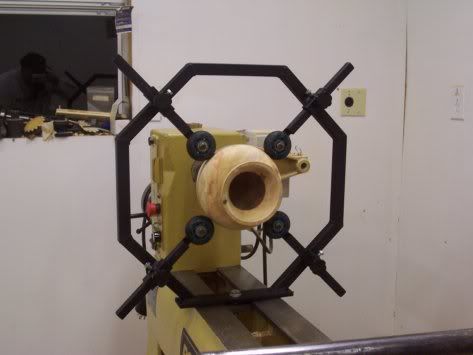

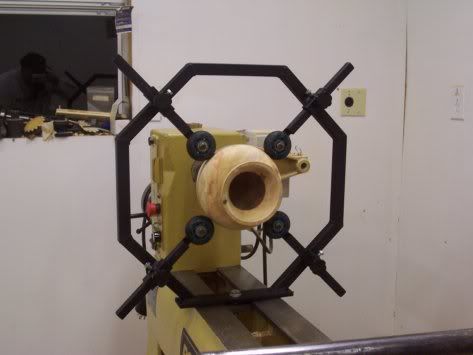

also I just finished up this Bowl/hollow form steady rest

I will copy and paste from another forum some info on it:

I have been putting off building this rest for a while. I was at the point doing all the hollow forms lately where it was a necessary item on the deep hollow forms to help keep the HF from being riped off the chuck, and also helping reduce chatter. I have built Mr. Big Mike Stafford a 4 wheeled steady and he informed me the design of the last one was bulky and needed to be reduced somehow ( it was square) Me and Mr. Travis Stinson had been talking in chat about what could be done to reduce the size and bulk of the original Steady and he come up with the great idea of making it a octagon shape. That has been over 10 months ago and I have been putting this off for that long Travis beat me to the punch, and already made his, He said it works great so I decided to go with his design.

and I will post one more tool I use everyday that I work on the lathe, its My version of the Wolverine grinding jig and Vari grind jig this pic was taken before I mounted it on a stand I made for it.

I have since cut off the skew sharpening rests on each side of the middle one. I got in the way of grinding some bowl gouges and I can free hand Skews better than the jig worked for them.

Here is the captured hollowing rig it also has a laser mounted on the arm thats above the cutting end of the rig but it was not on at the time of the pic its made from 1" pipe 3/4" pipe and 2 1/2" flat bar stock

also I just finished up this Bowl/hollow form steady rest

I will copy and paste from another forum some info on it:

I have been putting off building this rest for a while. I was at the point doing all the hollow forms lately where it was a necessary item on the deep hollow forms to help keep the HF from being riped off the chuck, and also helping reduce chatter. I have built Mr. Big Mike Stafford a 4 wheeled steady and he informed me the design of the last one was bulky and needed to be reduced somehow ( it was square) Me and Mr. Travis Stinson had been talking in chat about what could be done to reduce the size and bulk of the original Steady and he come up with the great idea of making it a octagon shape. That has been over 10 months ago and I have been putting this off for that long Travis beat me to the punch, and already made his, He said it works great so I decided to go with his design.

and I will post one more tool I use everyday that I work on the lathe, its My version of the Wolverine grinding jig and Vari grind jig this pic was taken before I mounted it on a stand I made for it.

I have since cut off the skew sharpening rests on each side of the middle one. I got in the way of grinding some bowl gouges and I can free hand Skews better than the jig worked for them.

Comment