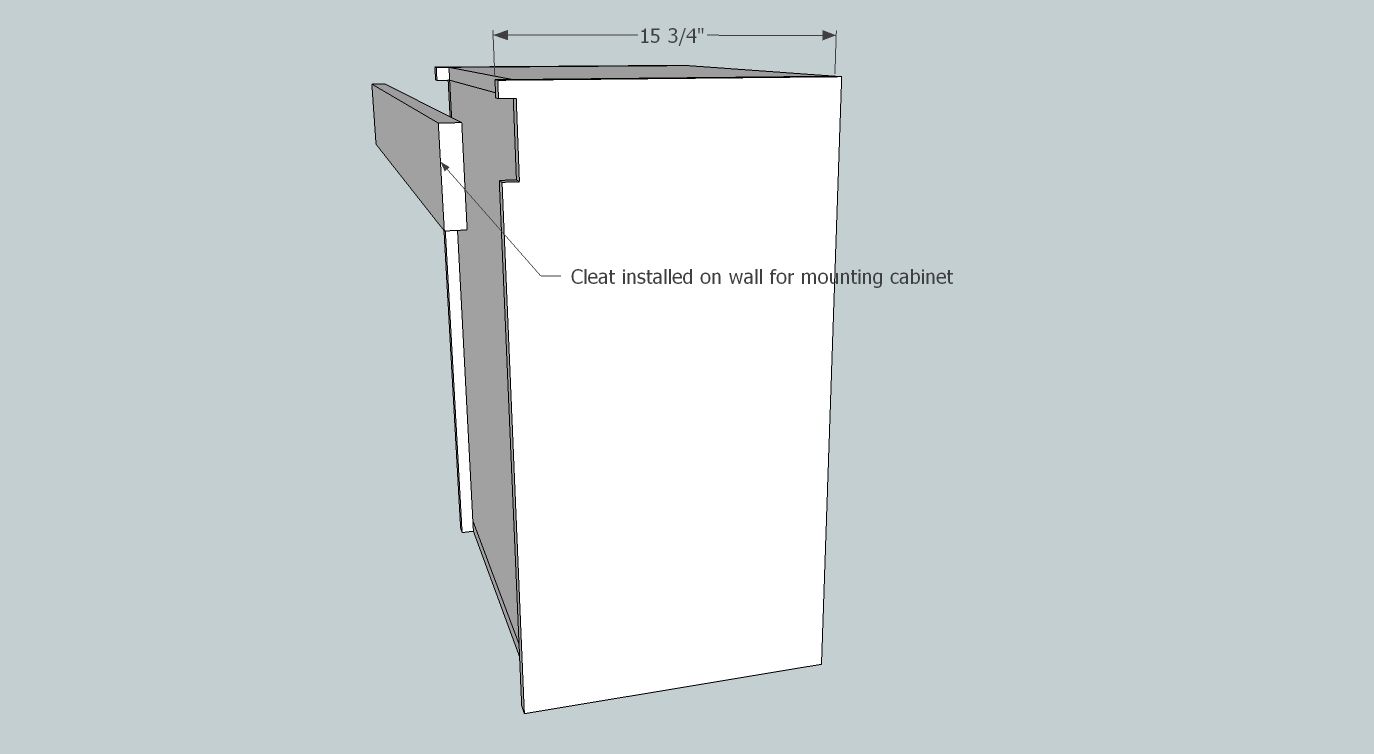

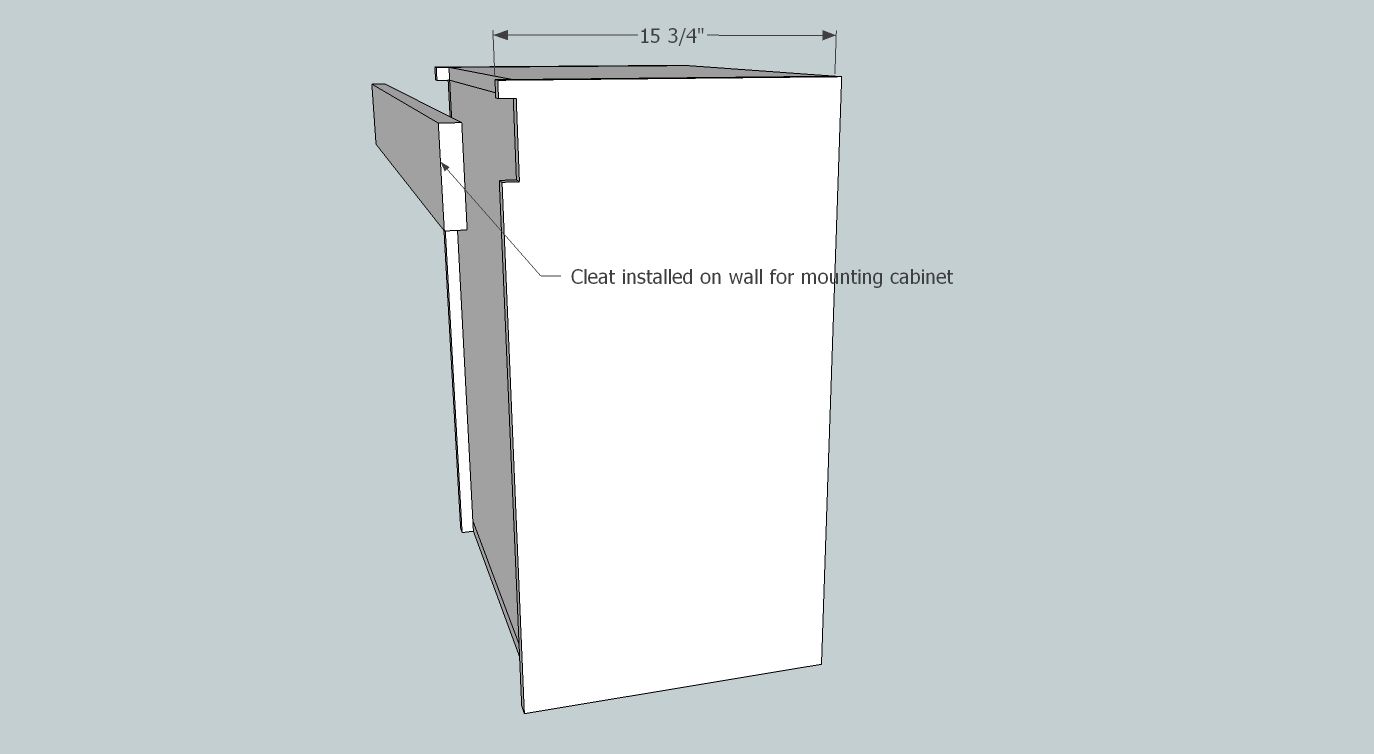

Has anyone used a method such as I have posted below? I don't know if I originated it or not, but I was thinking about installing cabs solo and wanted to use the french cleat idea, but thought about how sometimes ceiling's hang low in places and at times you may want the cab to be flush to the ceiling. This is what I came up with:

I understand that its not a locking cleat, but it would be enough to be able to set the cabinet freeing hands to level and fasten to the wall. What are your thoughts?

I understand that its not a locking cleat, but it would be enough to be able to set the cabinet freeing hands to level and fasten to the wall. What are your thoughts?

The way you are configuring the attachment, still positions the cabinet to the possibility of a low area within the width of the cabinet. Hanging tight to the ceiling presents that possibility even when there are no obvious inordinate discrepancies in the ceiling's surface.

The way you are configuring the attachment, still positions the cabinet to the possibility of a low area within the width of the cabinet. Hanging tight to the ceiling presents that possibility even when there are no obvious inordinate discrepancies in the ceiling's surface.

Loring in Katy, TX USA

Loring in Katy, TX USA

Comment