In a recent thread, I made a note of a mini-sawboard I made for squarely cross cutting boards. Ed and Twistsol posted a comment, so I decided to give the Squared Mini-Sawboard its own thread here.

Originally, I used a speed square in crosscutting with a circular saw, but I hated to do the precise measuring required for perfect alignment with the cutting line on the circular saw. So I first made a sawboard like spacer and butted it up against the speed square. This gave me easy and perfect alignment. Then I misplaced my 12 in speed square. I did have my spacer, so I decided to add an edge to it, and then I added a small cross piece glued to the bottom - carefully squared to make it align perfectly.

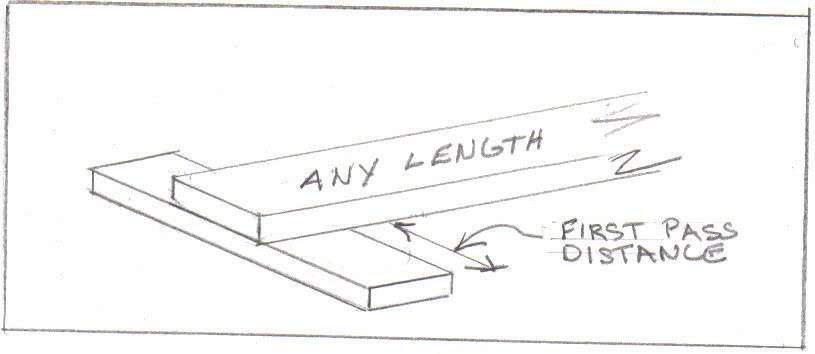

Basically, it is a sawboard on a mini-scale for crosscutting 12 in wide and narrower boards. If I were starting from scratch again, I would make the back board on the left side - several inches wider to allow clamping from that. As it is now, I place the mini sawboard in place and use another backer board against the sawboard and clamp the backer board. I like the small size because it doesn't take a lot of space and can be stored in a quick to reach place.

Very simple and very handy for cross cutting accurately with a circular saw.

Originally, I used a speed square in crosscutting with a circular saw, but I hated to do the precise measuring required for perfect alignment with the cutting line on the circular saw. So I first made a sawboard like spacer and butted it up against the speed square. This gave me easy and perfect alignment. Then I misplaced my 12 in speed square. I did have my spacer, so I decided to add an edge to it, and then I added a small cross piece glued to the bottom - carefully squared to make it align perfectly.

Basically, it is a sawboard on a mini-scale for crosscutting 12 in wide and narrower boards. If I were starting from scratch again, I would make the back board on the left side - several inches wider to allow clamping from that. As it is now, I place the mini sawboard in place and use another backer board against the sawboard and clamp the backer board. I like the small size because it doesn't take a lot of space and can be stored in a quick to reach place.

Very simple and very handy for cross cutting accurately with a circular saw.

Both of you know your tools and how to use them professionally. If I were doing WW professionally, I am sure my techniques and tools would change.

Both of you know your tools and how to use them professionally. If I were doing WW professionally, I am sure my techniques and tools would change. But the occasional user does!

But the occasional user does!

Comment