I bought the bandsaw I mentioned in the other thread - for all of $150  !

!

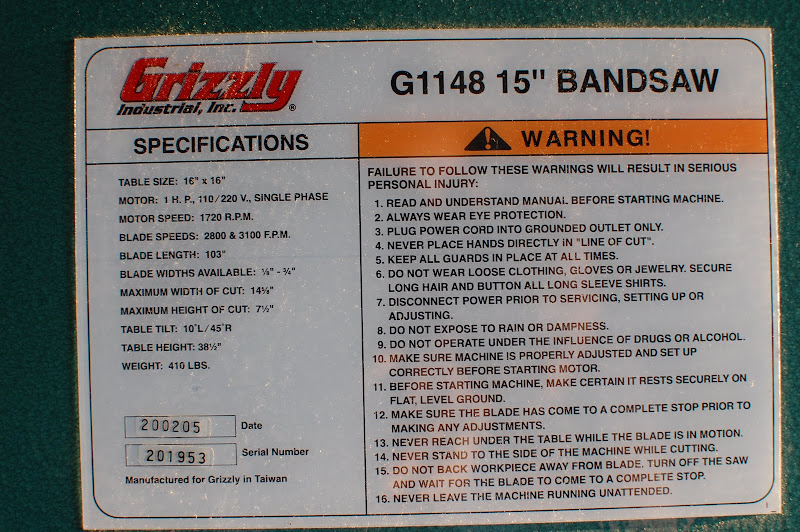

I know, it's a discontinued model, and there are pieces missing, but from what I've read of it, and that it is in excellent condition, I am happy with it.

A very funny buying experience - a new bandsaw sitting in the garage unused - and not even fully assembled - for some years. The guy has a garage full of Grizzly stuff and then got ill. His nephew attempted to assemble this bandsaw 2 years ago, but gave up before setting the table on. I turned it on and found it worked smoothly and quietly. By comparing with the parts list I found that the whole fence is missing, and the bracket to attach the table to the saw is missing. The garage is a huge mess now because his wife died recently and he moved in with his daughter. Both she and I tried to search for the missing pieces but had to give up. she promised that since all the garage is being cleaned up this month, if she finds anything she'll call me. Not holding my breath for that.

She didn't even argue when i dropped her asking by $50.

I don't really care about the fence, but checked with Grizzly : the bracket and etc will cost me $29. The fence replacement will cost me higher, but do you agree I could do better looking elsewhere for better, cheaper? maybe shopbuilt?

Very clean and new looking.

Year : 2002

Some TLC needed here.

I want to verify that the assembly was good; am thinking I could start by visiting some grizzly shop floor (woodcraft?) and seeing how the blade-guide-thingamajig is supposed to sit; this (above) looks too close for comfort.

And yes, might as well order another blade, right? It has a 1/2" now, so maybe a 3/16"? And do you think I need a spare or two? Do blades break often?

Observe that it is on the HF dolly for now. Need a mobile base too.

!

! I know, it's a discontinued model, and there are pieces missing, but from what I've read of it, and that it is in excellent condition, I am happy with it.

A very funny buying experience - a new bandsaw sitting in the garage unused - and not even fully assembled - for some years. The guy has a garage full of Grizzly stuff and then got ill. His nephew attempted to assemble this bandsaw 2 years ago, but gave up before setting the table on. I turned it on and found it worked smoothly and quietly. By comparing with the parts list I found that the whole fence is missing, and the bracket to attach the table to the saw is missing. The garage is a huge mess now because his wife died recently and he moved in with his daughter. Both she and I tried to search for the missing pieces but had to give up. she promised that since all the garage is being cleaned up this month, if she finds anything she'll call me. Not holding my breath for that.

She didn't even argue when i dropped her asking by $50.

I don't really care about the fence, but checked with Grizzly : the bracket and etc will cost me $29. The fence replacement will cost me higher, but do you agree I could do better looking elsewhere for better, cheaper? maybe shopbuilt?

Very clean and new looking.

Year : 2002

Some TLC needed here.

I want to verify that the assembly was good; am thinking I could start by visiting some grizzly shop floor (woodcraft?) and seeing how the blade-guide-thingamajig is supposed to sit; this (above) looks too close for comfort.

And yes, might as well order another blade, right? It has a 1/2" now, so maybe a 3/16"? And do you think I need a spare or two? Do blades break often?

Observe that it is on the HF dolly for now. Need a mobile base too.

Loring in Katy, TX USA

Loring in Katy, TX USA !

!

!

!

Comment